1 / 3

1 / 3Automated material handling with sheet metal parts

Hardware Price:

Pick rate

5

seconds

Lifetime

more than 3 Million

Cycles

DOF

5

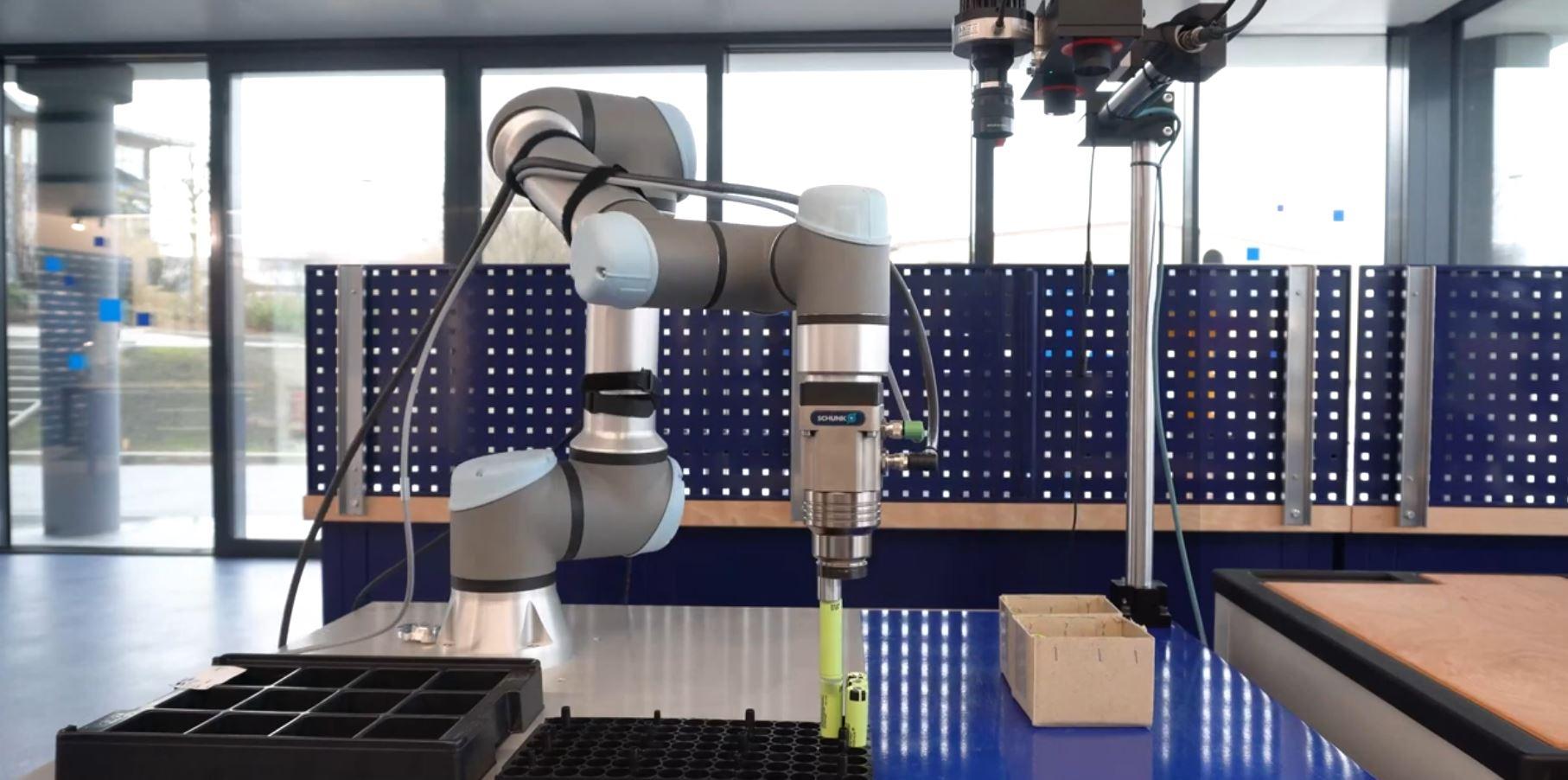

Automating Sheet Metal Pre-Sorting with igus Robolink DP 5-Axis Robot

Efficient pre-sorting of components is vital for streamlining production processes. In this application, an igus Robolink DP 5-axis robot, combined with a custom fixture, automates the pre-sorting of sheet metal parts. The robot picks up parts and places them at designated positions, enabling employees to access them for further processing. Its 790 mm reach and 3 kg payload make it ideal for handling small to medium-sized materials, while the option to integrate a drylin® seventh axis expands its workspace when required.

What is the Application?

The system automates sheet metal handling, supporting pre-sorting tasks in manufacturing environments to reduce manual effort and improve workflow efficiency.

What are the Advantages of the Solution?

Improved Productivity: Speeds up pre-sorting tasks, freeing employees for high-value activities.

Enhanced Flexibility: Compatible with a seventh axis for extended workspace.

Ease of Use: Simplifies programming through igus Robot Control software.

What are the Advantages of the Robot?

The Robolink DP 5 excels in component handling:

High Precision: Ensures accurate movement and placement.

Compact Design: Fits well within constrained production setups.

Custom Integration: Easily combines with specialized fixtures for tailored operations.

Optimizing Sheet Metal Sorting with Robolink DP 5

The igus Robolink DP 5 robot provides an effective solution for automating pre-sorting processes. Its adaptable design, ease of programming, and compatibility with expanded workspaces make it an invaluable tool for improving productivity in manufacturing operations.

2 Components