1 / 3

1 / 3Automated stacking and unstacking of metal rings with a room gantry

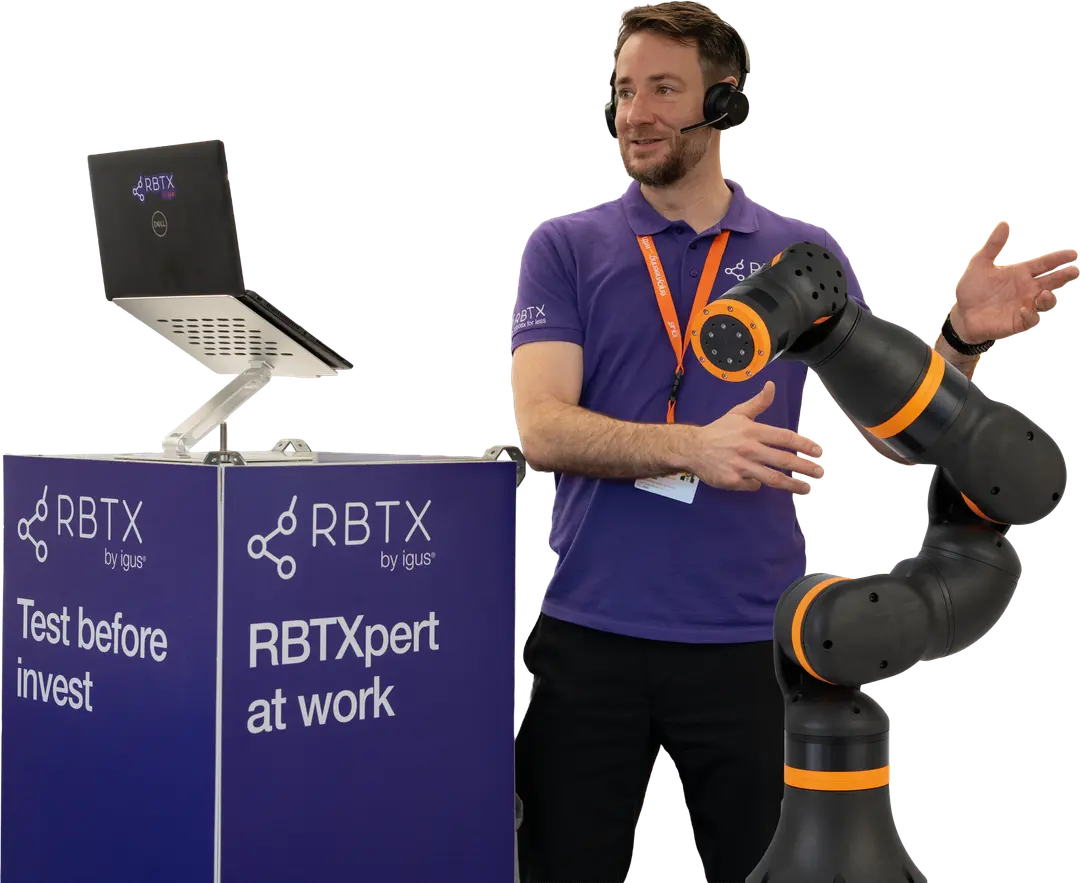

Test Before Invest

Hardware Price:

DOF

3

Working space

400x400x150

mm

Max. payload

5

kg

igus Portal Robot in Action: Stacking and Unstacking Metal Rings

In the Customer Test Area (CTA), an igus portal robot demonstrated its ability to automate the stacking and unstacking of metal rings. Featuring igus components like energy chains and polymer plain bearings, the robot performed precise and efficient movements, showcasing its suitability for industrial process automation. The low-maintenance and durable design of igus products ensures reliable operation, even in demanding environments, making this solution ideal for repetitive material handling tasks.

What is the Application?

The system automates material handling tasks such as stacking and unstacking metal rings, optimizing workflows in manufacturing and logistics.

What are the Advantages of the Solution?

High Durability: igus products withstand rigorous operations over time.

Low Maintenance: Reduces downtime and servicing costs.

Precision Movements: Ensures accurate stacking and positioning of components.

What are the Advantages of the Robot?

The igus portal robot stands out for:

Customizable Use: Easily adaptable to various handling tasks.

Smooth Operation: Polymer bearings provide frictionless movement.

Energy Efficiency: Optimized design minimizes operational costs.

Enhancing Automation with igus Portal Robots

The igus portal robot exemplifies how robust components and precise movements can transform material handling. Offering durability, low maintenance, and reliability, this system is a cost-effective solution for industries looking to streamline processes and improve productivity in demanding workflows.

2 Components