1 / 3

1 / 3Five-axis robot tests keyboard

Hardware Price:

Pickrate

3

seconds

DOF

5

Max. payload

3

kg

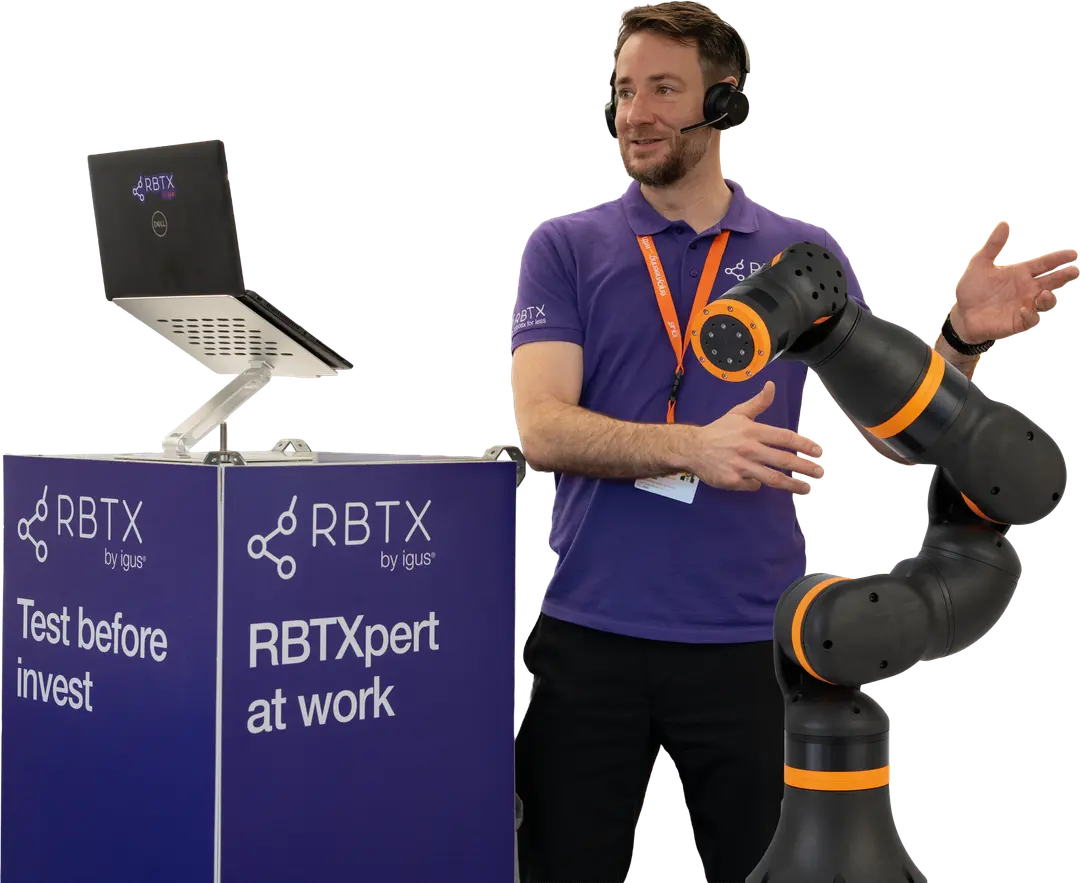

Automating Keyboard Quality Control with Robolink DP 5

Multi-axis robots are ideal for automating quality control processes, and in this example, a Robolink DP 5-axis robot efficiently tests each individual key on a keyboard for functionality. With a reach of 790 mm and a maximum payload of 3 kg, the Robolink DP 5 is well-suited for precise and repetitive tasks. If additional working space is required, the robot can be mounted on a drylin® seventh axis, significantly extending its range. Programming is straightforward using the igus Robot Control, making it easy to adapt the robot for specific applications.

What is the Application?

The Robolink DP 5 automates keyboard functionality testing, ensuring reliability and consistency in quality assurance processes for electronics manufacturing.

What are the Advantages of the Solution?

High Accuracy: Tests individual keys with precision and repeatability.

Extended Range: Easily expandable with a seventh axis for larger workspaces.

Efficient Integration: Streamlines testing processes for mass production.

What are the Advantages of the Robot?

The Robolink DP 5 offers:

Versatile Movements: Multi-axis design for complex testing workflows.

Ease of Programming: Intuitive software simplifies application setup.

Durable and Reliable: Robust components ensure longevity in demanding environments.

Optimizing Quality Control with Robolink DP 5

The Robolink DP 5-axis robot showcases its ability to automate precision testing, like keyboard functionality checks, with efficiency and adaptability. By reducing manual intervention and offering scalability, this solution enhances production workflows while ensuring high product quality standards.

1 Component