1 / 3

1 / 3SCHUNK - Intelligent sorting system

Hardware Price:

DOF

6

Repeatability

0.03

mm

Max. payload

3

kg

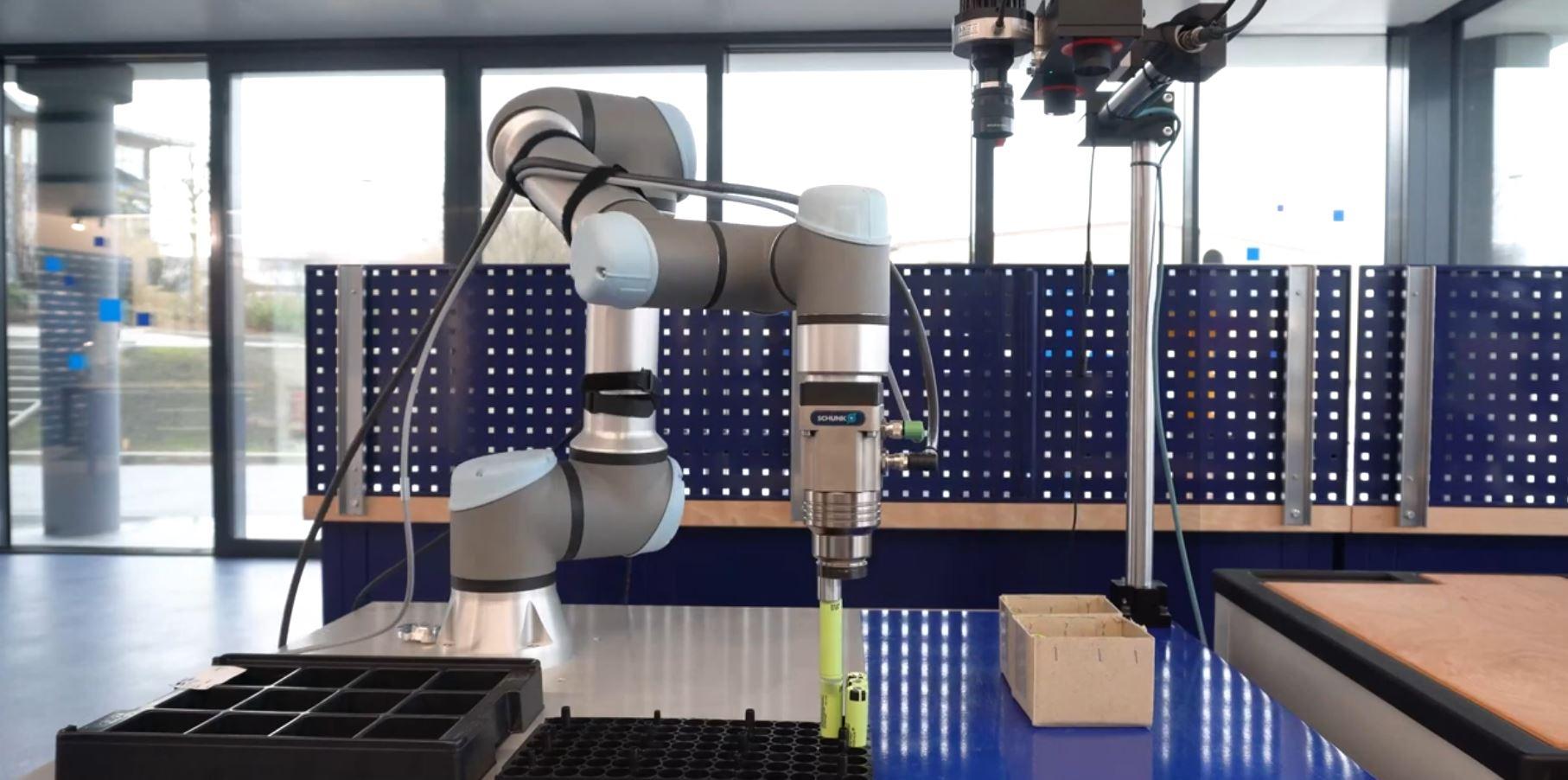

Automated Pick-and-Place with SCHUNK SGC and Varioshaker

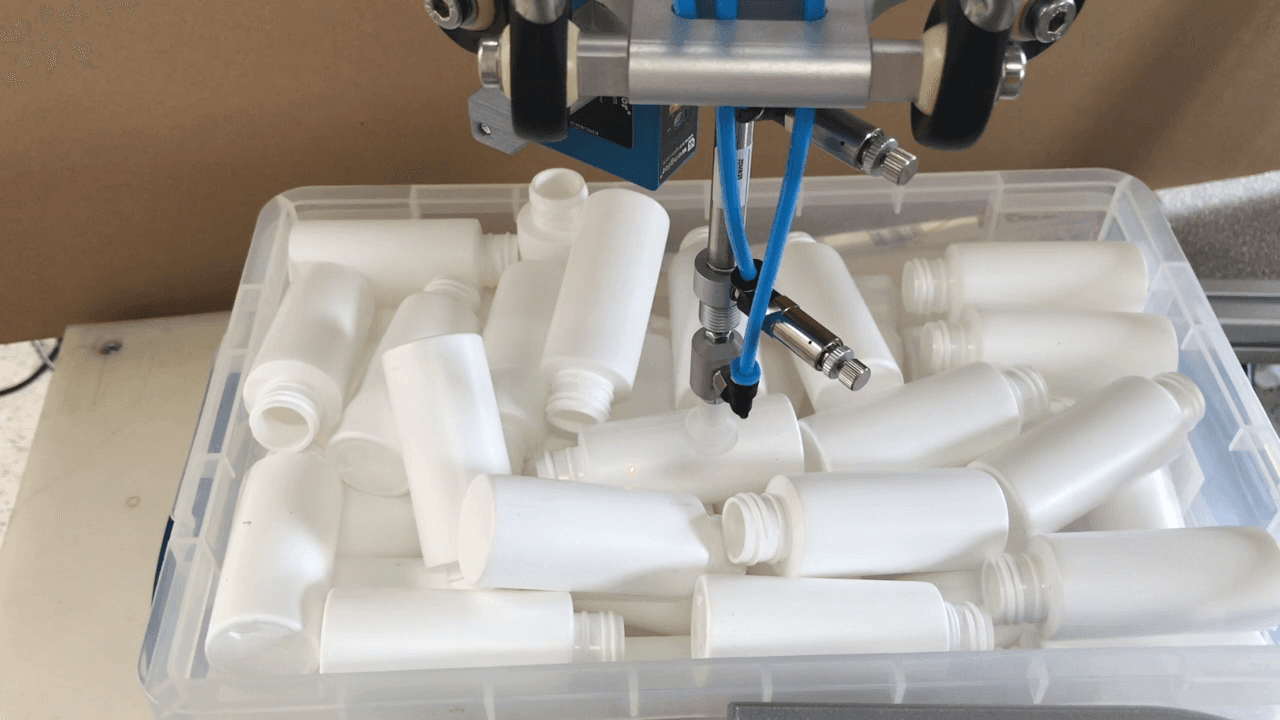

SCHUNK demonstrates the efficiency of fully automated pick-and-place tasks with this innovative application. A UR3e articulated-arm robot, equipped with the SCHUNK SGC system, works alongside the Varioshaker 270 to reliably detect and handle components. The SGC combines a gripper and a perfectly integrated camera, enabling the robot to locate parts on the Varioshaker. The Varioshaker’s vibration function realigns components into optimal positions, ensuring precise and efficient handling.

What is the Application?

The system automates pick-and-place tasks for components with inconsistent alignment. The Varioshaker repositions parts, while the robot identifies and grips them, streamlining workflow.

What are the Advantages of the Solution?

Error Prevention: Realigns misaligned components, reducing idle times.

Efficiency: Eliminates manual intervention, increasing throughput.

Cost Savings: Minimizes downtime and idle costs.

What are the Advantages of the Robot?

The UR3e robot with SCHUNK SGC excels in high-precision tasks:

Integrated Vision: Combines camera and gripper for seamless operations.

Precision Handling: Ensures reliable detection and gripping.

Compact Setup: Fits easily into diverse production environments.

Optimizing Pick-and-Place with Intelligent Automation

This solution from SCHUNK CoLab highlights the synergy of the UR3e, SGC system, and Varioshaker, offering a robust and scalable setup for precise pick-and-place applications. By reducing errors, improving efficiency, and minimizing downtime, the system enhances productivity and reliability in automated workflows.

4 Components