1 / 3

1 / 3Sideloader robots for autonomous warehousing

Hardware Price:

Flexibility

high

Mobile

Robot

Construction

DIY

AMR with igus Surface Gantry: Streamlining Storage and Picking Automation

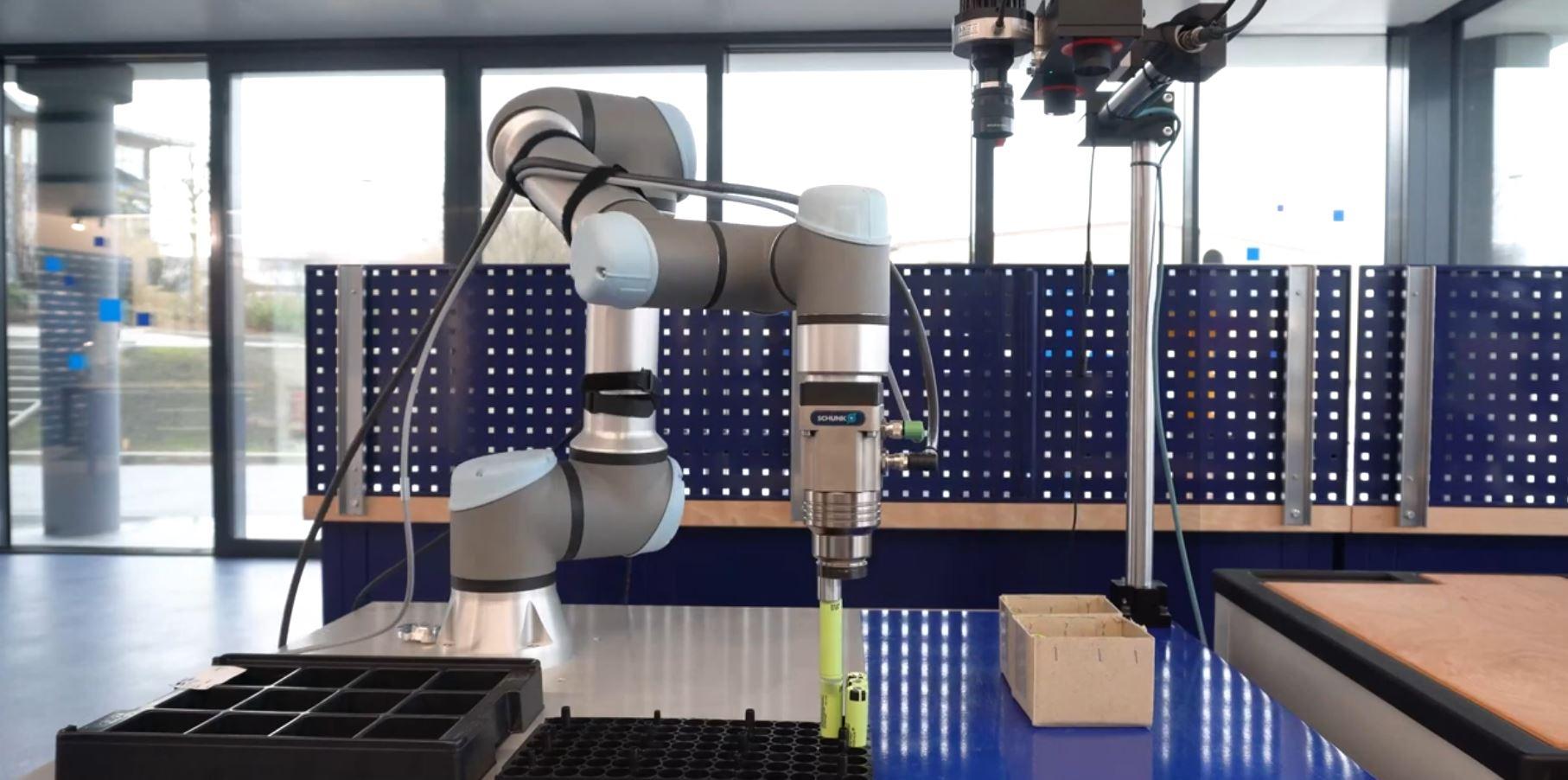

This video showcases an Autonomous Mobile Robot (AMR) equipped with an igus surface gantry that serves as a precise guide rail. The robot is designed to autonomously remove boxes from shelves, optimizing operations in storage and picking processes. By leveraging the reliable and accurate motion of the igus gantry system, the robot ensures efficient workflows and reduces manual workloads. Suitable for industries such as logistics, retail, and manufacturing, this setup highlights the transformative impact of robotics in improving productivity and streamlining operations.

What is the Application?

The AMR automates box picking and transportation, enabling autonomous navigation and handling in storage environments for improved efficiency and accuracy.

What are the Advantages of the Solution?

Enhanced Efficiency: Reduces personnel workload and speeds up picking tasks.

High Precision: igus gantry ensures accurate movements.

Versatile Adaptability: Applicable across multiple industries, including logistics and retail.

What are the Advantages of the Robot?

The AMR integrated with the igus gantry offers:

Seamless Navigation: Autonomous movement ensures reliability.

Reliable Operation: Durable gantry components enable continuous functionality.

Scalability: Easily adaptable for various storage configurations.

Boosting Productivity with AMR and igus Gantry

The combination of AMRs and igus surface gantries exemplifies how automation can revolutionize storage and logistics workflows. Offering precision, efficiency, and versatility, this innovative solution enables businesses to enhance productivity and optimize their operations in modern industrial environments.

0 Components