1 / 3

1 / 3The 7th axis for the ReBel

Hardware Price:

DOF

6

Construction

with 7th axis

Project costs

12,218.47

€

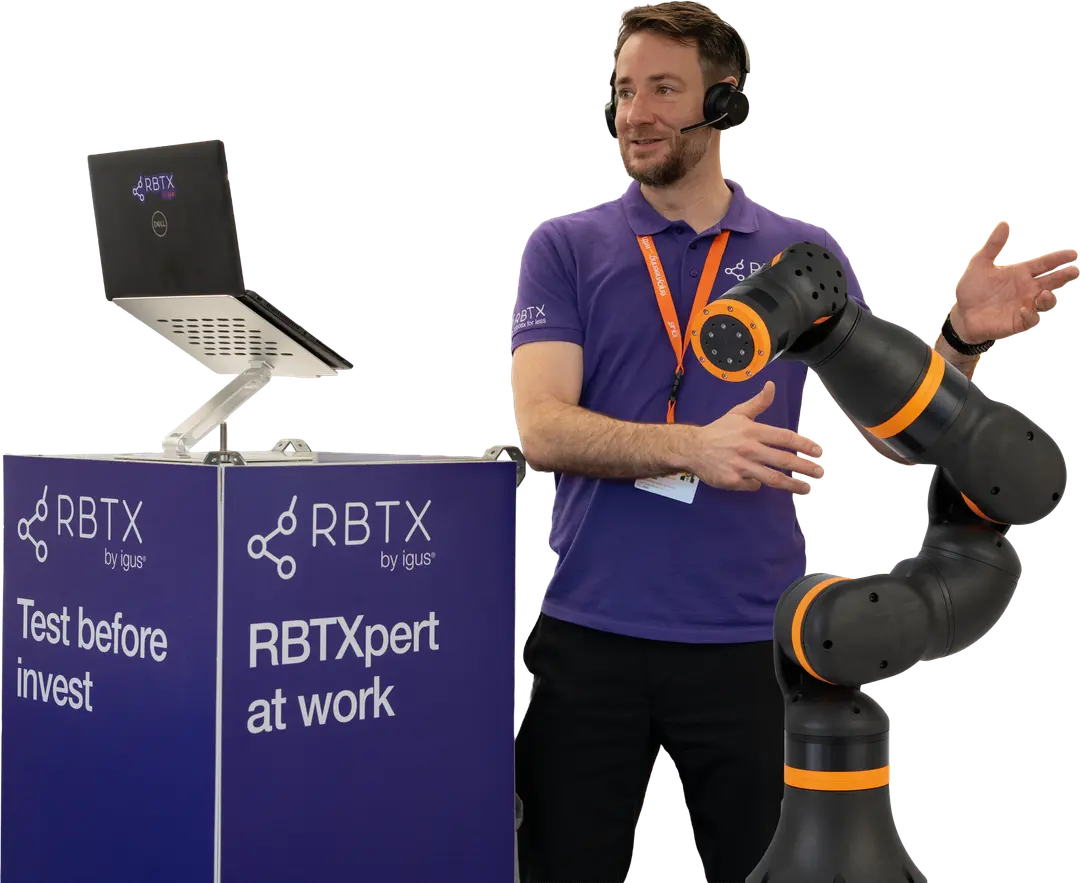

Extended Reach with igus Seventh Axis: Boosting Robotic Versatility

Many applications require robots to operate beyond their initial workspace. The seventh axis from igus® extends the robot's action radius by a factor of four. Utilizing a ZLW-20 toothed belt axis with adapter and a matching energy chain set, this system provides a standard stroke length of up to 3000 mm, extendable to 6000 mm upon request. Compatible with both igus robots and lightweight models from manufacturers like Universal Robots (including UR CAP integration) and EPSON, the seventh axis delivers a highly versatile and scalable automation solution.

What is the Application?

The seventh axis enhances robots in applications requiring linear extension of workspace, such as material handling, pick-and-place, and assembly tasks across large areas.

What are the Advantages of the Solution?

Extended Reach: Increases workspace range by up to 6000 mm.

Wide Compatibility: Usable with igus and third-party lightweight robots.

High Scalability: Meets varying operational demands with customizable stroke lengths.

What are the Advantages of the Axis?

The igus seventh axis provides:

Precision: Accurate positioning with toothed belt drive.

Durability: Built with robust materials for long-term use.

Flexibility: Seamlessly integrates with existing robot applications.

Optimizing Automation with the igus Seventh Axis

By extending the robot's workspace, the igus seventh axis enables manufacturers to take full advantage of automation. Whether used with igus robots or third-party models, this solution enhances productivity, flexibility, and scalability—making large-scale applications both feasible and efficient.

1 Component